Syngenta

Safe seed coating on a laboratory scale

At seed improvement company Syngenta in Enkhuizen, costly seeds are coated with plant protection products by hand on stainless steel work tables. New laminar flow booths with bottom exhaust systems keep the exposure risks for workers well below the legally required minimum levels.

Enkhuizen

At dusk, the greenhouse complexes alongside the offices, production areas and laboratories of Syngenta in Enkhuizen are lit up beautifully. Horticultural crops and flowers are cultivated here for improvement research. The advanced small seeds that emerge can cost several euros a piece. The flowers and horticulture sector can thus increase its yields, reduce the use of chemicals, improve quality and maximum profits. The coating of these valuable seeds with crop protectors is a delicate process and is therefore done manually on a laboratory scale. Up until last year, the Coating division still worked with localised extraction to protect workers from exposure to substances.

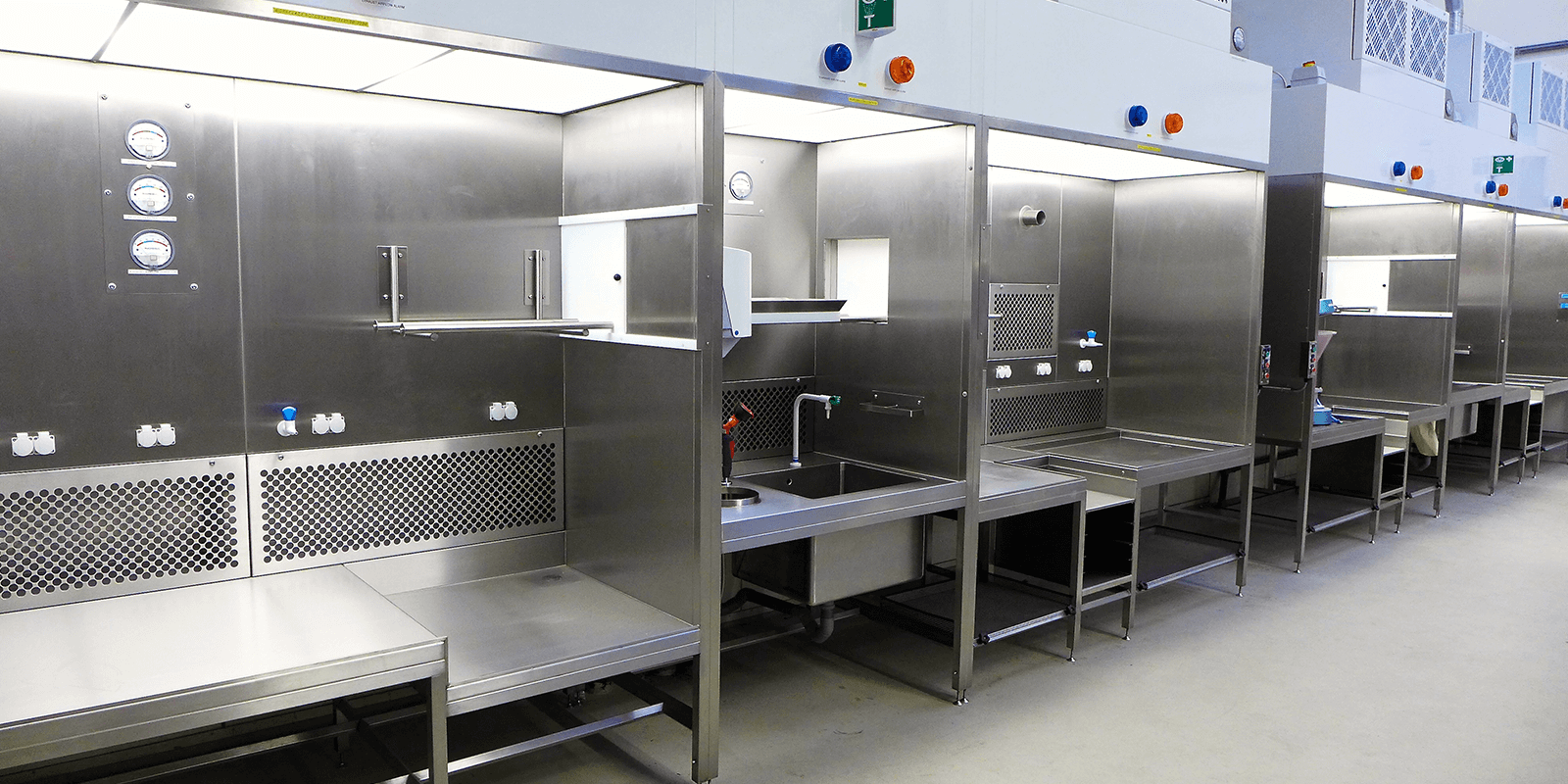

Syngenta thus met the occupational health and safety requirements, but the company wanted to go a step further to remain well below the exposure limits now and in the future. This led to the decision to integrate three workplaces and two washing rooms in laminar flow booths. The downward air flow from the ceiling to the rear of the work tables and booths keeps hazardous substances out of the breathing zone. Validation of the units points to a significant improvement in the air situation and thus an improvement in the occupational health and safety conditions of the workplaces.

Precision Work

In the Coating division, workers spray various types of liquid over the seeds in a sort of pan. The agents protect seeds, which come from worldwide cultivation programmes, for example against fungus. This coating on a laboratory scale is real precision work. After each series, the worker determines the final weights to see whether the correct amount of crop protector has been used and checks the seeds for adhesions.

No seed may be lost, and there are fine sieves in the sink to catch everything. After each batch everything is checked, there must be no foreign seeds at all in a coated batch. The lab then checks for features not visible to the eye that the coating must possess. The batches vary from grams to kilos.

Syngenta Standards

“We want minimum contact with the agents for our workers” says Jeroen Greiner. He is project manager in the facilities division and coordinated the project with the laminar flow booths. “We spray the slurry straight onto the seeds. These products are not good for people’s health. With the old localised extraction, the exposure was too high by Syngenta standards. We met all the legal safety requirements, but Syngenta sets the bar high within the crop protection sector.

The requirements in that regard are implemented throughout the company, in other words also rolled out to the seed division. We wanted to gain more control over the situation here logistically and in terms of substance management. These are toxic agents, lighter than coffee whitener. Such localised extraction works well on the coating machine, but less so in the surrounding area, where you have to tip the seeds out”.

Safe Barrier

There followed a search for a suitable solution. “In the preliminary stage, we focused on the offer together with an engineering firm. I had already seen the principle of the new set-ups we chose on the DENIOS stand at a trade fair. At the time it already appealed to me. That became the starting point for the design of an installation with which we create a safe barrier between the worker and the process. This is guaranteed by the air management of the booth. We had three built for coating and two in which washing rooms with eye showers were integrated,” says Greiner.

Units with tables were chosen, whereby the booth cannot be entered. Greiner: “We felt it was easier to place the apparatus on tables in the cabinet, from where the air is extracted straight to the outside via a central exhaust system. A return system was less appealing to us, because if there’s a disaster with the filtration installation you run the risk of dust being carried into the cabin via the return line. The extracted air passes through a high-efficiency heat exchanger. So we’ve physically separated the air system, but we can recover as much energy as possible for hall heating”.

Trial Model

Right from the start Greiner involved his colleagues in the plans. He first had the set-up with the tables in a booth tested in practice. “CCD installed a trial model of MDF board in a steel frame on site. This allowed workers to experience whether the theory actually works in practice. One time right, that’s what we were aiming for.” The experiences revealed specific needs that were implemented in the final design. “The platform was adapted and the steel bucket for the seeds is now height-adjustable.

There was also a request for a water barrier round the edge and a grille under the tables. To organise the booths properly, they wanted a plank in each unit to put things on. We work according to the 5s principle, everything has a fixed and logical place”. All in all, quite a few areas for improvement. “Here you can see the added value of the trial model. By involving workers in the design process from an early stage, you create a well-thought-out and feasible design”.

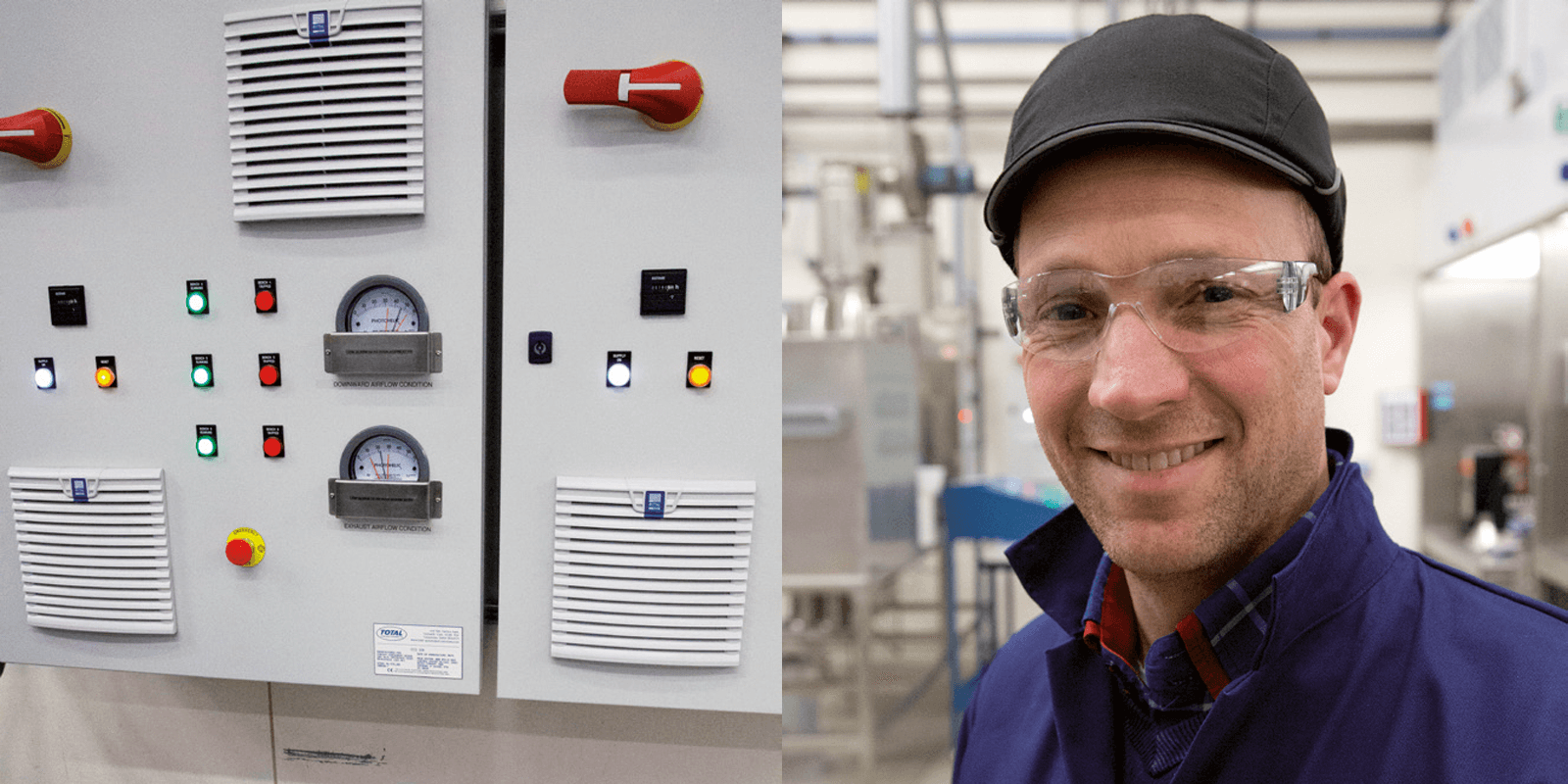

FAT and SAT

Six weeks later the Factory Acceptance Test (FAT) took place at the manufacturer in England. A test to check the cabinet from the perspective of ventilation. During the FAT we also closely examined the finish of the sockets and intake points. The finishing touch was the raised edge of around one centimetre. The surface of the table must be perfectly smooth to be able to make the sheet clean, but if you spill liquids, the raised edge means you can keep everything manageable within the table”. At the Site Acceptance Test (SAT) in Enkhuizen everything seemed to work perfectly.

“We carried out the SAT in consultation with the filter installation supplier. It has to ensure sufficient suction capacity. We checked all the safety features. Only when the light comes on and the afzuiging is working there is also power to work. If the afzuiging is not working, the coating machine must be switched off and remain off until this has been rectified. All alarms were also checked. In the booth, the operator can see visually whether it is safe to work. This is only possible if the light is on”.

Leading The Way

In January a stationary test was performed with concentration measurement on the open side of the cabinet, where the operator works. This shows that the situation has improved significantly. “If we put the measurement data from the periodic health and safety at work study next to each other and compare the old and new situation, then we can say that Syngenta are leading the way in terms of health, safety and the environment.

We want to be well below the standards. When you know that the requirements are becoming ever stricter, you have to include technical provisions for this in your design. These cabinets will be in use for ten to fifteen years, and all that time they will have to constantly meet the legal standard. A safe and healthy working environment is extremely important to Syngenta”.

Training

The installations were installed plug and play, so that the process could continue. “During the SAT, workers in the project team were instructed in the process and the cabinet. With this information, main users can guide their colleagues through the new process.

This meant we could commission the system quickly. There was also basic training for users and the technical service, to allow them to remedy any initial faults”.

Download Brochure

Submit your details to download a brochure.

Download PDFDetails which you provide here will not be shared with anyone outside of Concept and will be kept in a safe and secure location. You may request your personal data to be removed at any time.

We may obtain data from carefully selected third parties, including our clients. For more information read our privacy policy.