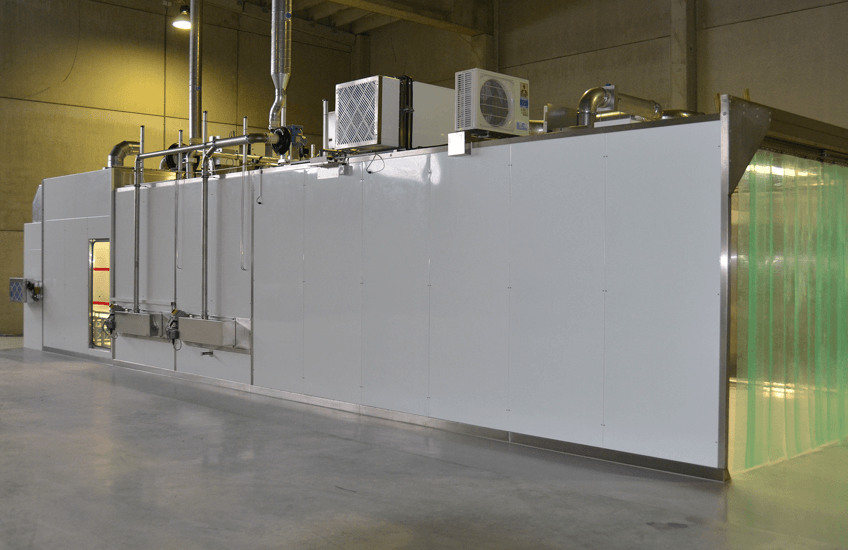

Containment Facilities

These bespoke facilities are designed from the ground up to exactly suite the required processes and maximise the potential of the available space. Containment facilities provide cGMP environments and briefly comprise of a downflow booth system complete with operator and material airlocks along with operator changing area and emergency shower.

Sampling Facility Unit

Sampling Facility complete with Materials Entry / Exit,

Lifting Hoist, Personal Airlock, Materials Airlocks with

automatic conveyors and Sampling Containment Booth

System. Include automatic IPA disinfection section.

- Design complies with the User Requirement Specifications for Sampling for small and large packages

- Internal full stainless steel. Outer sidewall double skin construction, zintec steel, epoxy polyester powder coated panels

- Clear anti-static strip-curtain entry in two sections mounted on slide-rails

- Above the facility, a Dx Condenser rated for 22.0kw of cooling provides air to the facility at 21 degrees

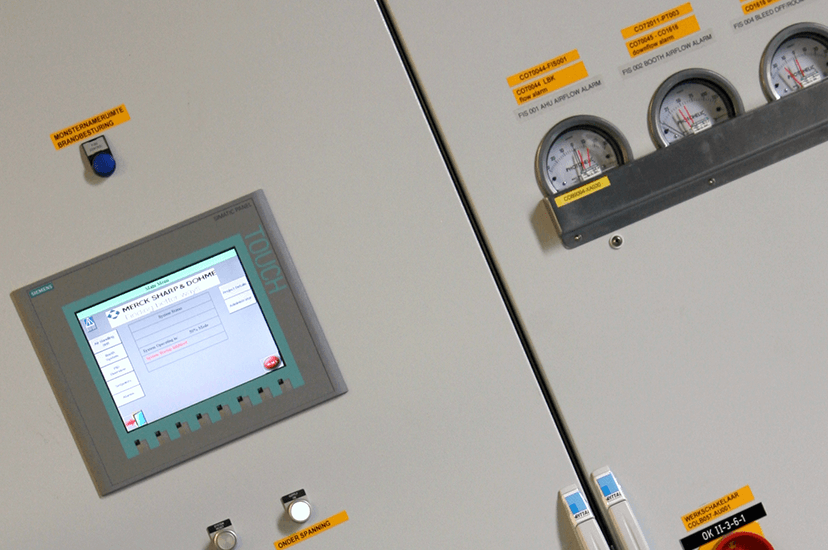

- Operating Modes Siemens PLC Controlled

Material Entry / Exit

- 10 air changes per hour

- Air quality ISO 8

- Pallet protection rails

- Stainless steel roller tracks

- Automatic glass sliding doors

- Intercom communications system

- Local operator controls station for raise / lower doors

- Vacuum lifting system for the loading and off-loading of bags and containers

Product entry automated conveyor system leading through a IPA spray disinfecting chamber followed by a IPA drying chamber ensuring any items are fully disinfected before any samples are taken.

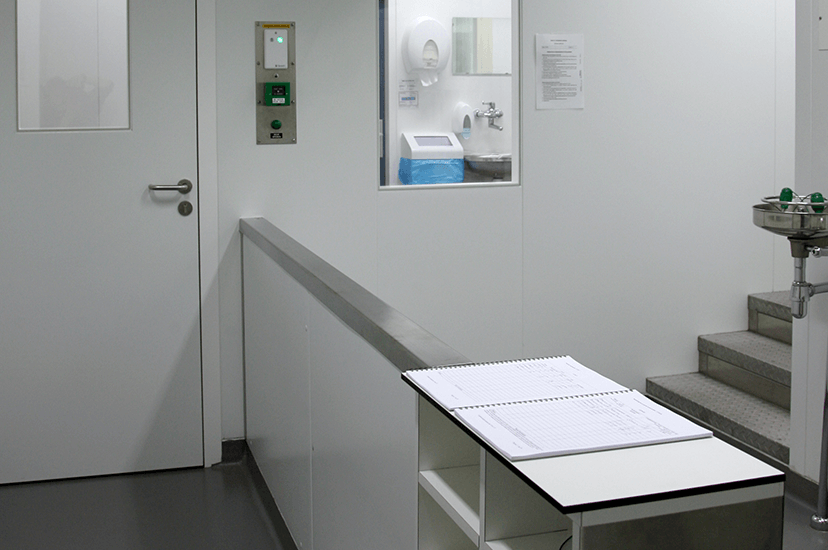

Personnel Airlock

- Minimum 10 air changes per hour at 25 Pa

- Air quality ISO 7

- Airlock doors with kick-plates and magnetic interlocks

- Interlock with emergency overrides

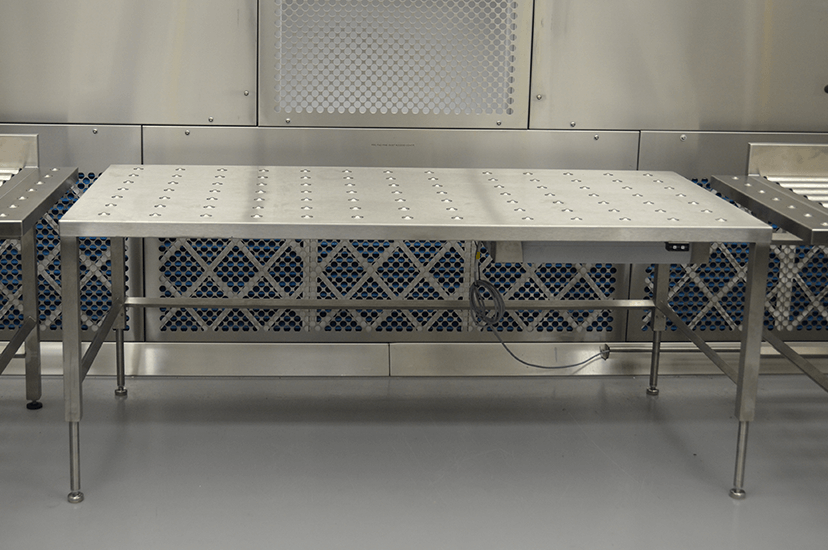

- Stainless steel Step-over bench

Facility containment booth complete with product roller track and raise/lower roller table to suit the ergonomics of different operators.

Booth working area complete with emergency removal section of roller track and a emergency kick-out panel/exit.

Containment Finishing Suite

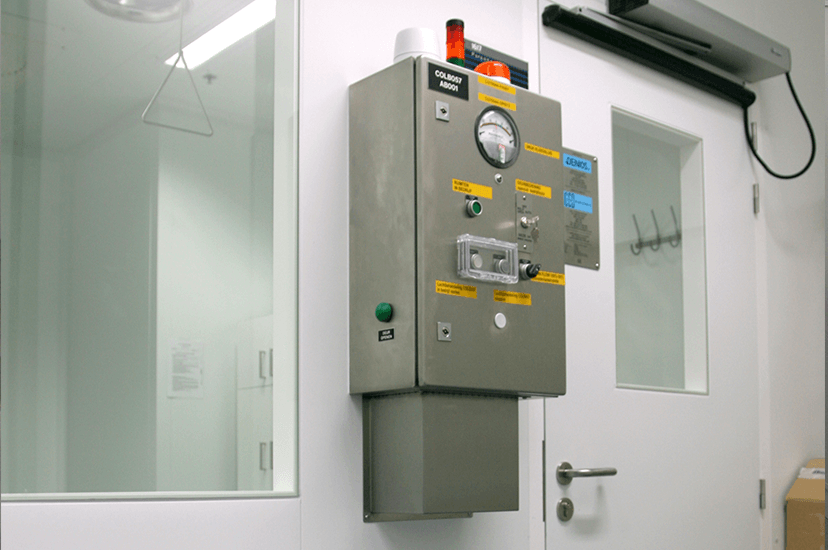

Local operator panel at suite entrance giving operators mode control, alarm and facility condition status before entering the changing room.

Pallet entry / exit door

High-speed, self-repairing automatic sliding door, fitted with open/close limit switches.

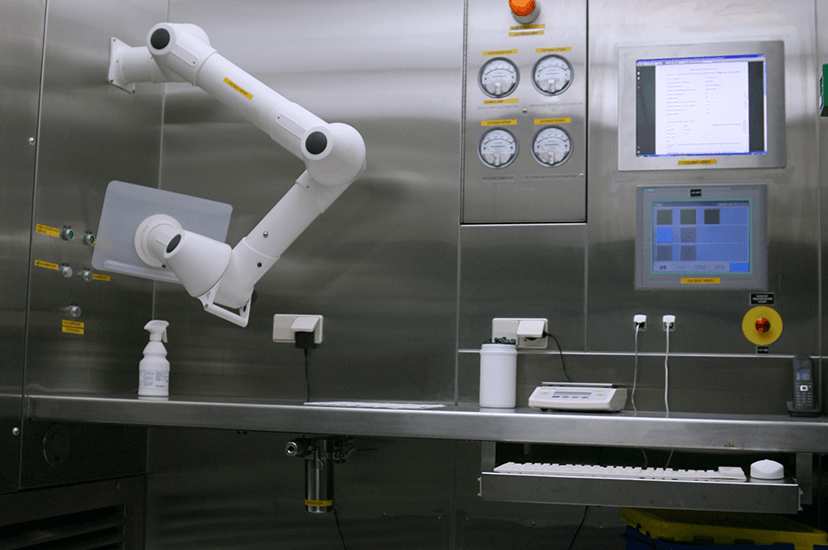

Sampling Booth Control Panel

Fully automatic airflow adjustment with 50% standby and 100% operational modes to operate at -10 Pa with Small reach dedicated extraction arm over the table for sampling small containers with solvents.

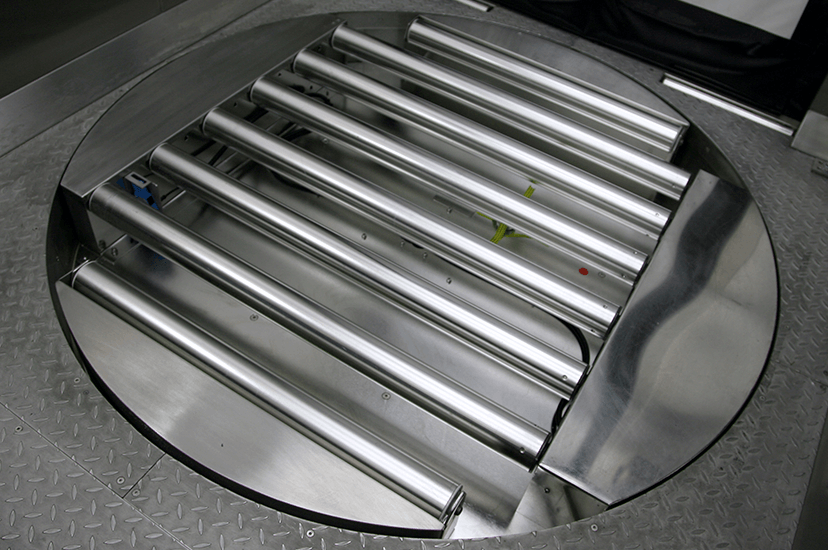

Pallet turntable

Heavy Duty Stainless Steel 316L in floor Sampling booth. Controlled from the HMI screen inside the booth and interfaced with the main conveyor system.

Main control panel

With Siemens S7-300 PLC and 10” HMI screen.