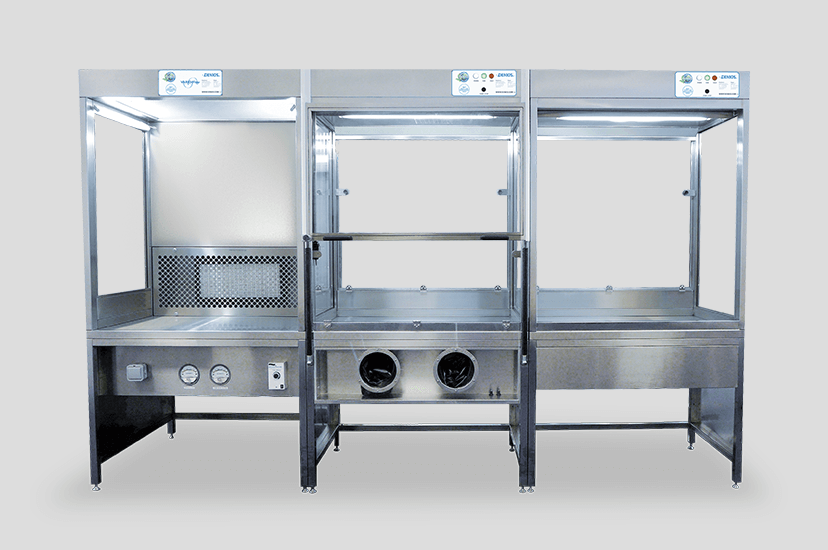

Bench Containment

Laminar downflow containment bench units operating with either a recirculation or single-pass airflow formats can be designed to suit smaller spaces or operations that do not require the size of a downflow booth system.

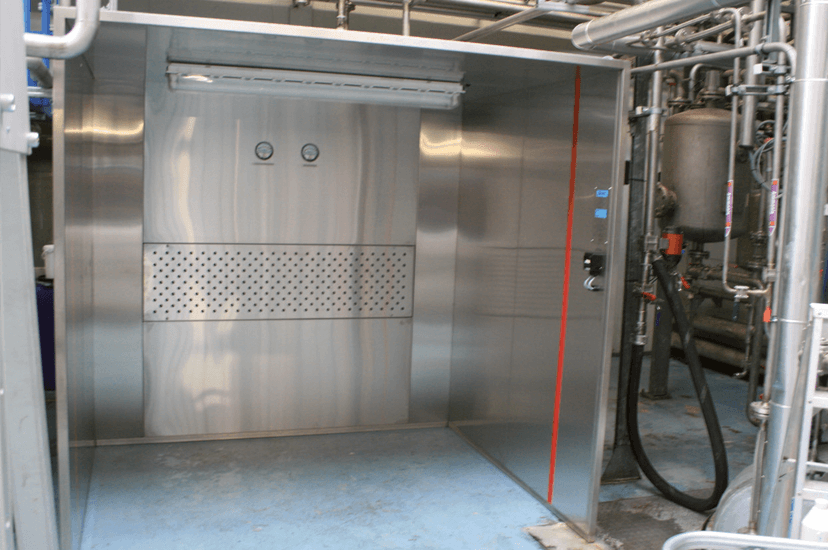

Recirculation

Recirculation bench unit with hopper and dedicated extraction, connected to a reactor.

Recirculation

In a recirculation system, 100% of the air is extracted by a high-efficiency fan/drive system, whilst providing automatic fan volume control to overcome the pressure drop as the filter dust burden increases.

Single Pass

Laminar downflow containment Bench Units, Single-Pass downflow, operating a constant negative pressure.

- Full stainless steel grade 316, 240s polished construction

- Laminar Downflow at 0.35 m/sec when measured 50 mm below PLF distribution screen frames

- Supply and exhaust airflows complete with safety operational interlocks

- Supply airflow plenum fitted with G4 pre-filter and F9 fine dust filters 98% efficient

- System lighting levels >600 Lux at 1.5 m above floor level, fitted with high-frequency T5 fluorescent lights

- Bench top and adjustable height section

- Equipment pass-through aperture with nylon sliding door

- Removable perforated equipment shelves

- Supply airflow drawn from room environment, downflow at 0.35 m/sec. at 50 mm below PLF screens

Single Pass

In the Single-Pass once-through system, 100% of the air supply is provided by a dedicated high-efficiency fan / filter system with pre-pad, fine dust and HEPA filters, providing a downflow of clean filtered air whilst pushing any respirable dust downward and away from the operator’s breathing zone.

Varioflow

A single exhaust fan those above an almost closed closet is placed, as with traditional fume cupboards, however, is not very effective and the almost always existing sliding window also limits the freedom of movement considerably. The blowing is much more effective or blowing in the air. Compare once extinguishing a candle by means of air sucking with the deaf to blow.

Varioflow

A Varioflow system offers safety protection at level 2 in a high-performance and efficient way of utilising ejector technology.

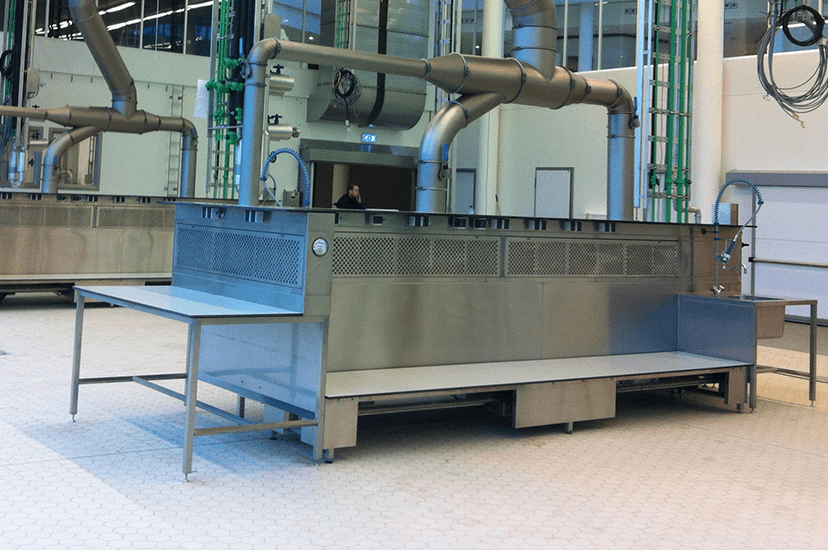

Horizontal Flow

Raise / lower bench unit with horizontal flow exhaust plenum allowing ergonomic working heights and containment for a wide range of vessels and applications.

Horizontal Flow

The airflow direction for a horizontal flow unit depends on the process to be carried out in the unit, outward filtered airflow for product protection or inward airflow (Negative) through filters for containment and operator protection.